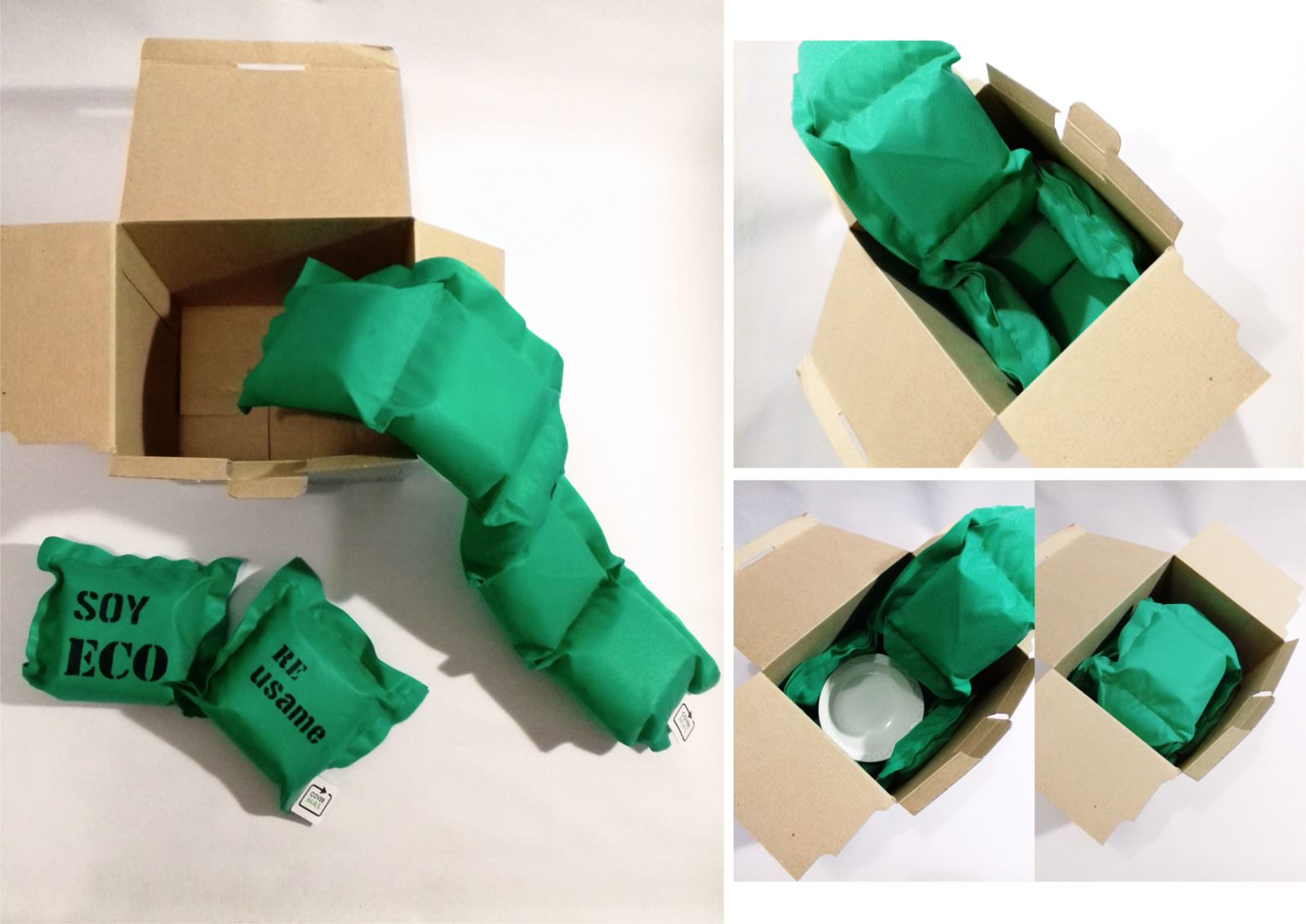

CoverMas, reusable shock absorber packaging

Packaging Solutions

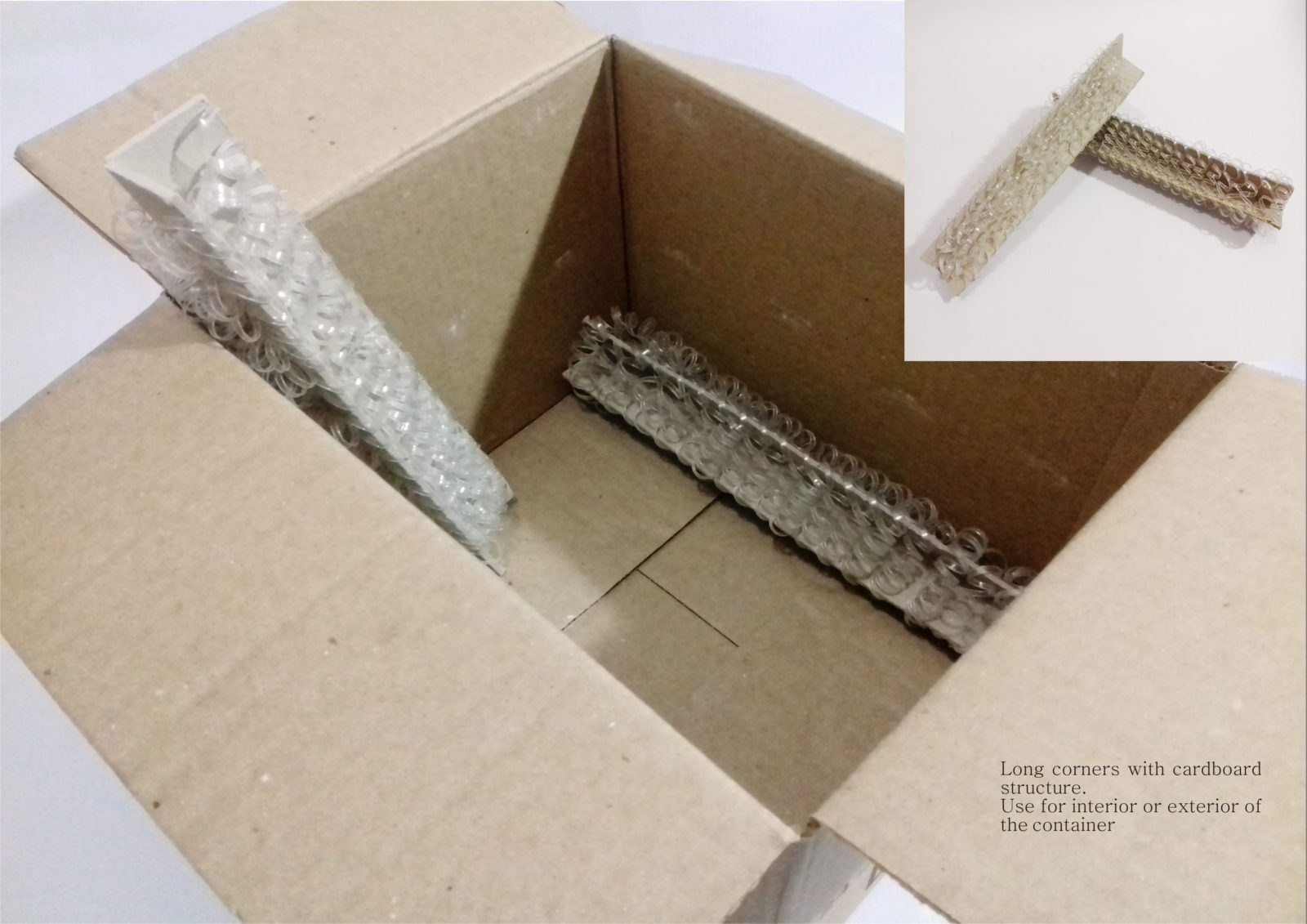

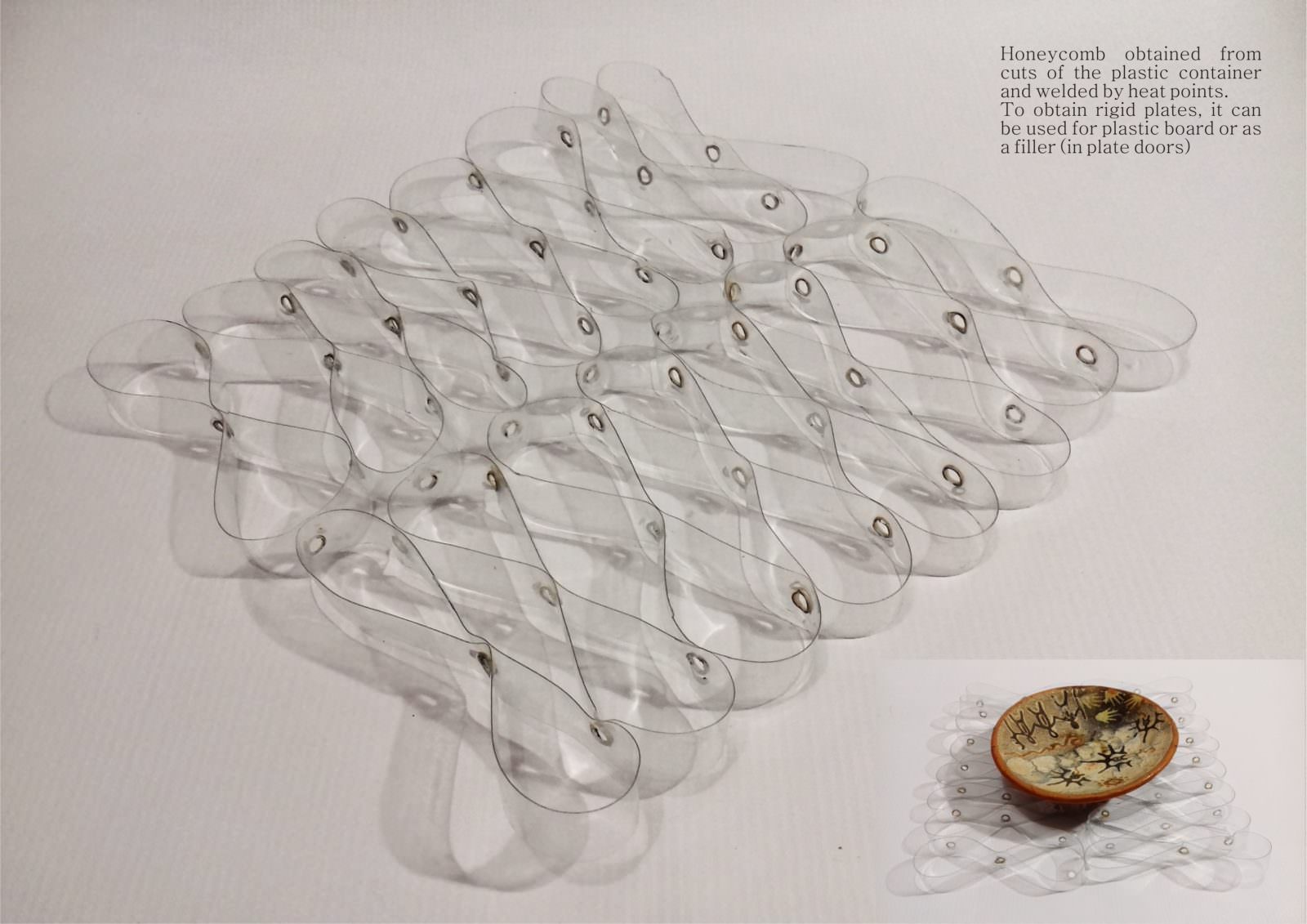

It consists of reusable protective packaging for the ecommerce sector, for the shipping and transport of fragile products, cushioning blows inside the packaging to prevent breakage. The cushioning system is manufactured from disposable plastic bottles of P.ET. (polyethylene terephthalate) , while the coatings use textiles to promote reuse (which improve consumer perception) and recyclable materials such as cardboard, which allow the exchange of damaged parts and separation for subsequent recycling. Covermas avoids losses in the distribution cycle and returns of products, reducing costs in the e-commerce sector; uses 90% of each plastic bottle, generating new local job opportunities for urban waste collection cooperatives. In addition, it reduces the amount of packaging inside a box, without affecting its ability to protect the fragile product. From cuts, and transformation of the material by heat, springs are generated, which depending on the functionality or product to be protected, vary in size and typology: * pads * protective plates * corners * separators for bottles * honeycombs * elastic / adjustable strips These springs are formally adapted to the products and isolate them from the surfaces, because an empty space is created, thus avoiding vibrations and absorbing the impact of the blow towards the product. Just as pallets and transport containers in good condition are resold on the web to continue their life cycle, this cushioning packaging pretends the same. In this way, with simple productive processes, the plastic that is reused from a bottle can protect the fragile products of many users and continue to be efficient for a longer time, until finally the wear or tear of each package ends up being recycled in a plant with more complex productive processes.