ELETTROSHOCK

Conscious Innovation Projects

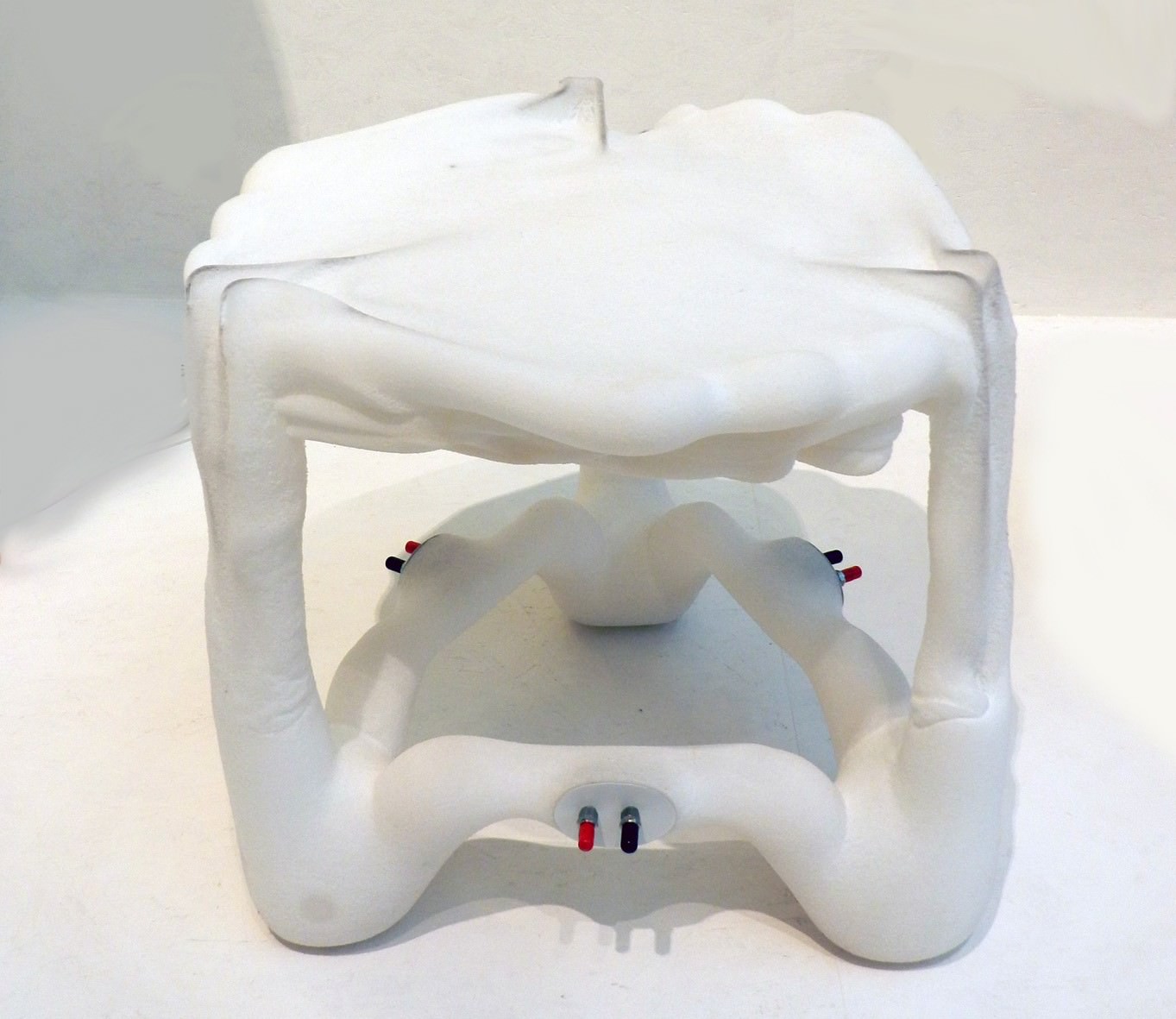

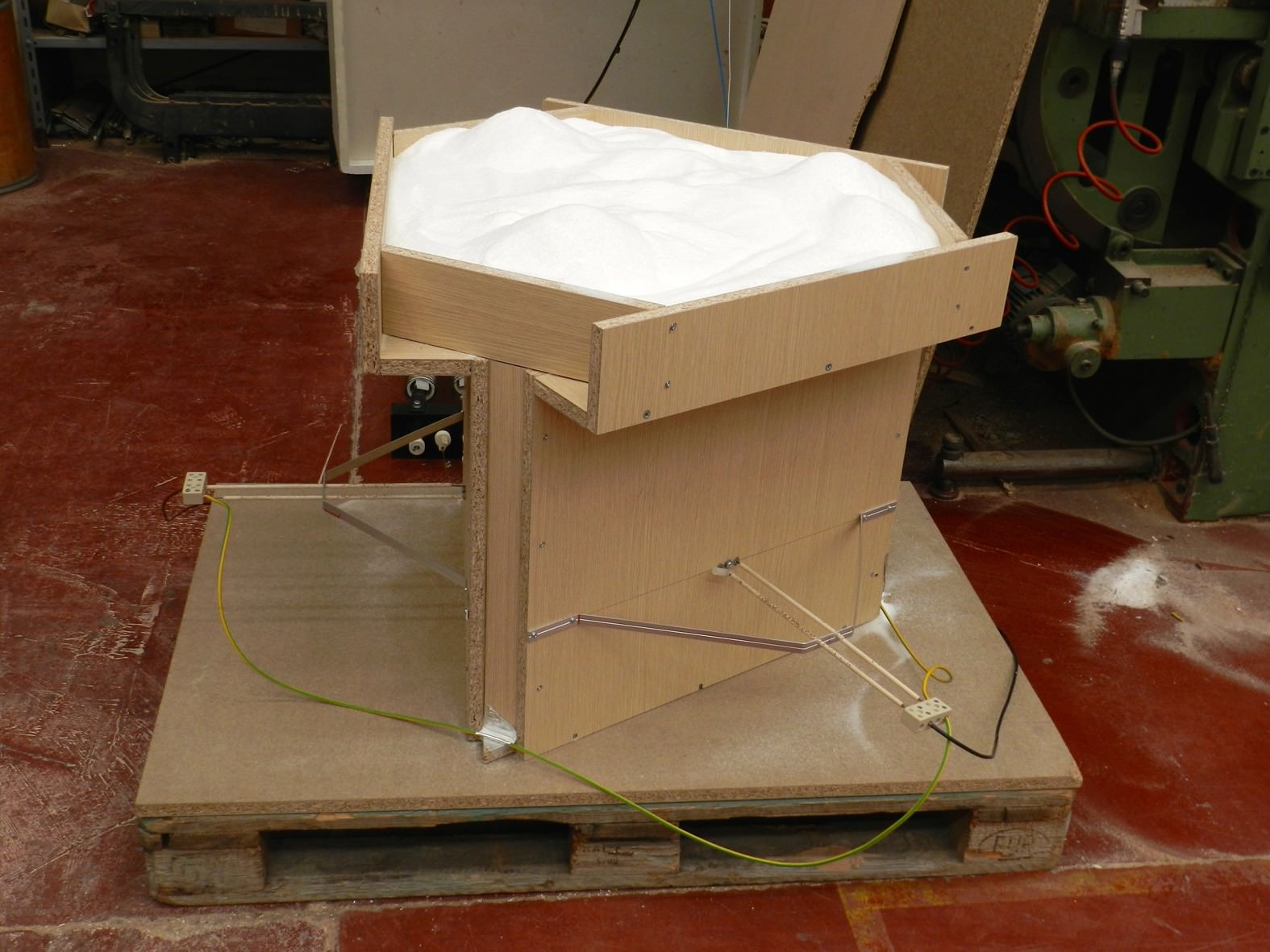

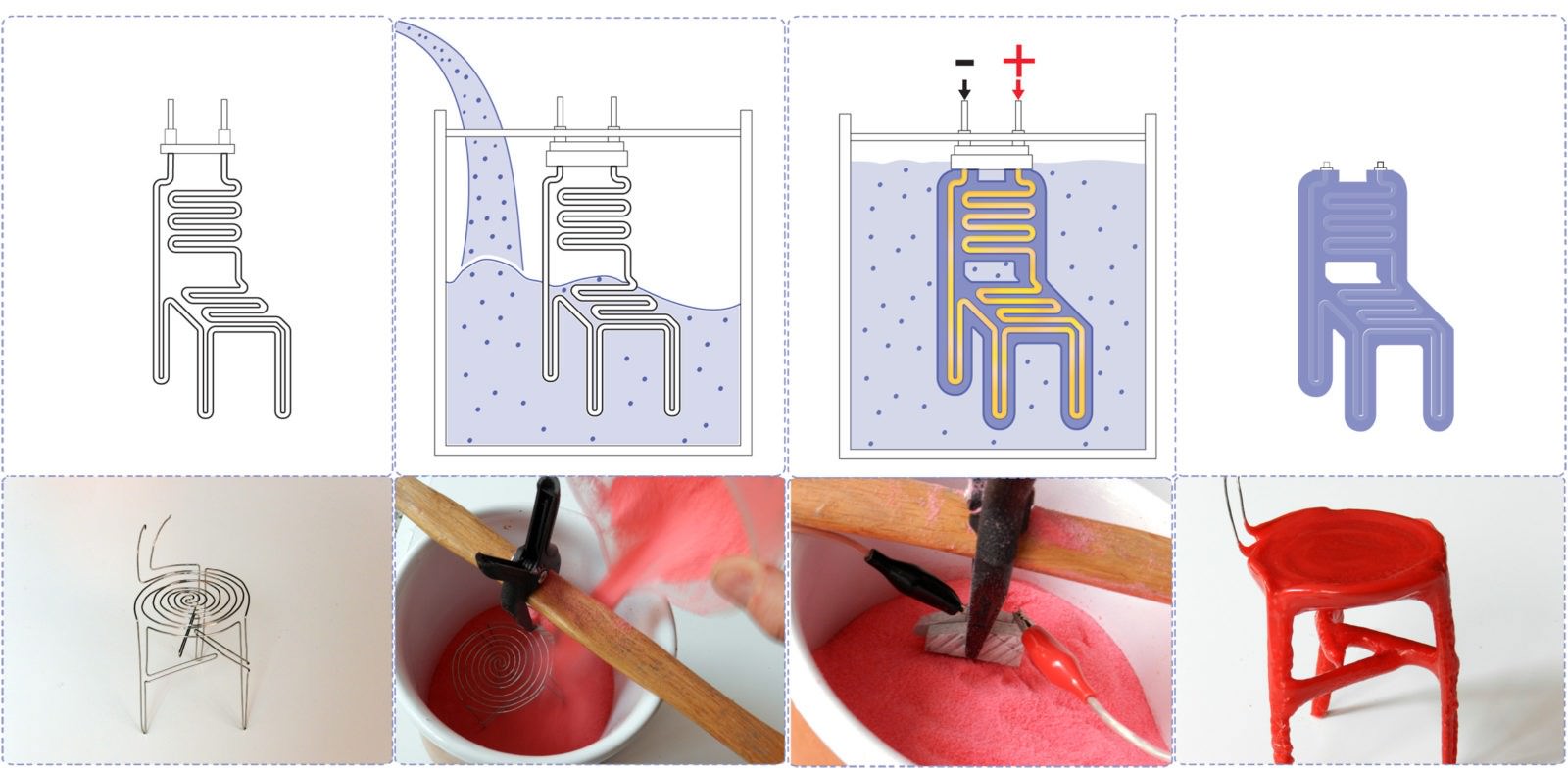

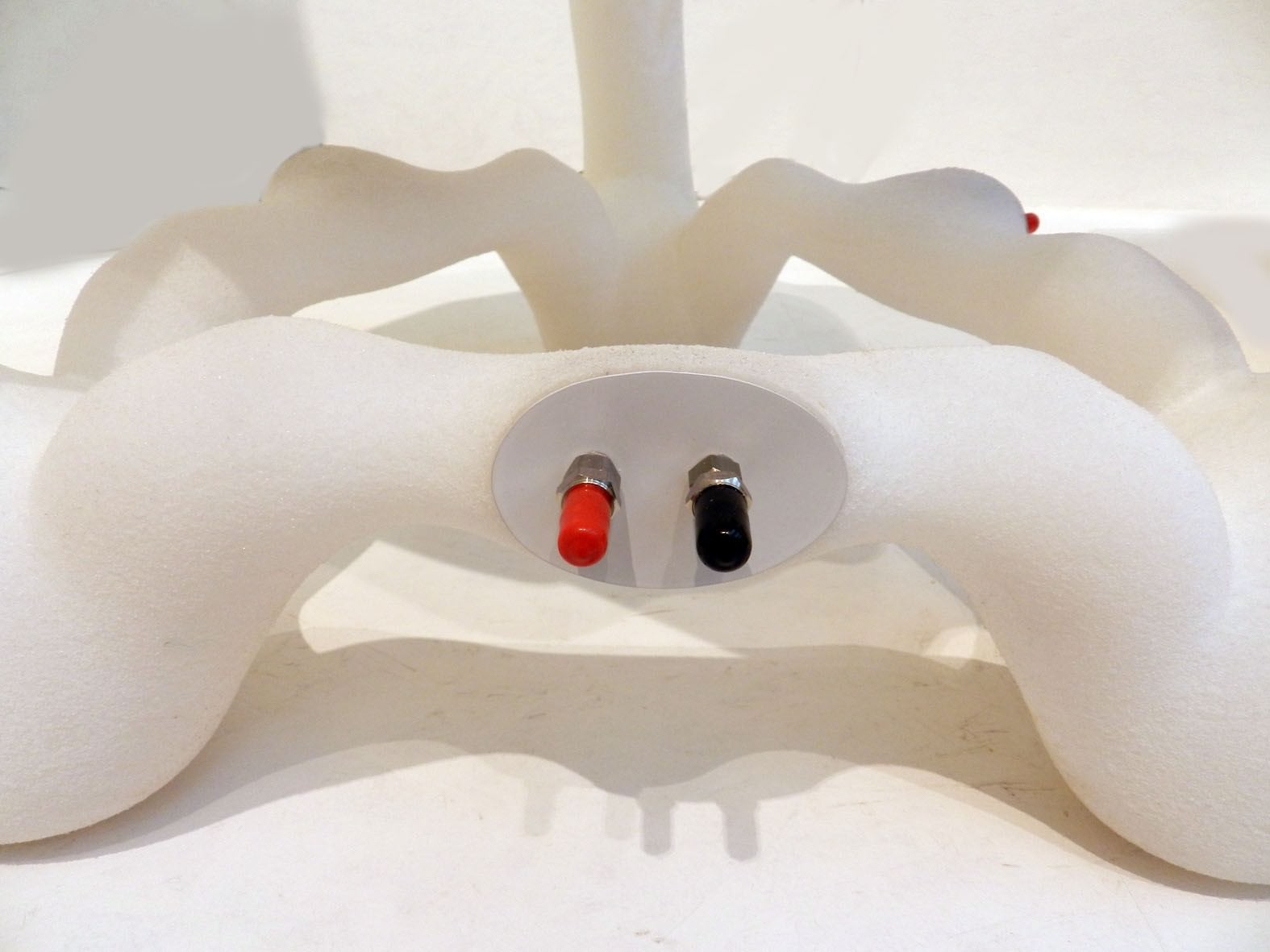

The recovery of plastics used in industry entails a considerable use of resources and energies, but such recovery is now indispensable. The awareness in the use of plastic as an indestructible material and with extraordinary features should lead us to its most conscious and legitimate use, paradoxically, when you think about it, plastic comes from a natural resource of thousands of years of deposits of organic debris!! In my opinion the key relevant to this matter are: – APPROPRIATE USE OF ANY MATERIAL – MINIMUM USE OF ENERGY FOR PRODUCTION – CONSUMER AWARENESS OF CHOICE – NOT WASTE – RECOVERY This my project of ‘system’ to build household objects is outlined in these main items: the recovery and use of plastic in its form of common industrial use, powder or granules, the reduction of energy to the minimum necessary for production by renouncing the construction of metal moulds and large production plants that are very energy-intensive, the possibility of differentiated and personalized production without economic aggravation, employment of more labour and human handicraft resources. The process involves the fusion of the polymer thanks to the heat generated in a metal wire resistant by the passage of electric current. The shaped resistive wire defines the formal skeleton of the object you want to make, once covered with powder or polymer granules, you can apply the electric current and the wire will melt as it heats the polymer that is around forming the supporting structure of the plastic object. The power supply is interrupted and the process stops, the cooling begins and the powder or the excess granule is removed(reusable) and the solid plastic object is obtained, having employed a quantity of energy comparable to the household use of a hairdryer or other appliance. The diameter of the resistive wire, its length and the temperature to be reached for fusion are the parameters to be calibrated according to the object to be 3/5 built. Light objects can also be constructed using the inner metallic wire as an electrical conductor: first it generates the shape (fusion) and then, applying low voltage controls, powers the light sources subsequently applied. This process is renewable every time power is supplied, therefore it is essential to leave on the object the feeding poles, well visible and which can also emphasized aesthetically the genesis of the object itself, and if you want to recover the material and produce a different object just reactivate the process to get the detachment of the two materials and be able to reuse them for the creation of another object.