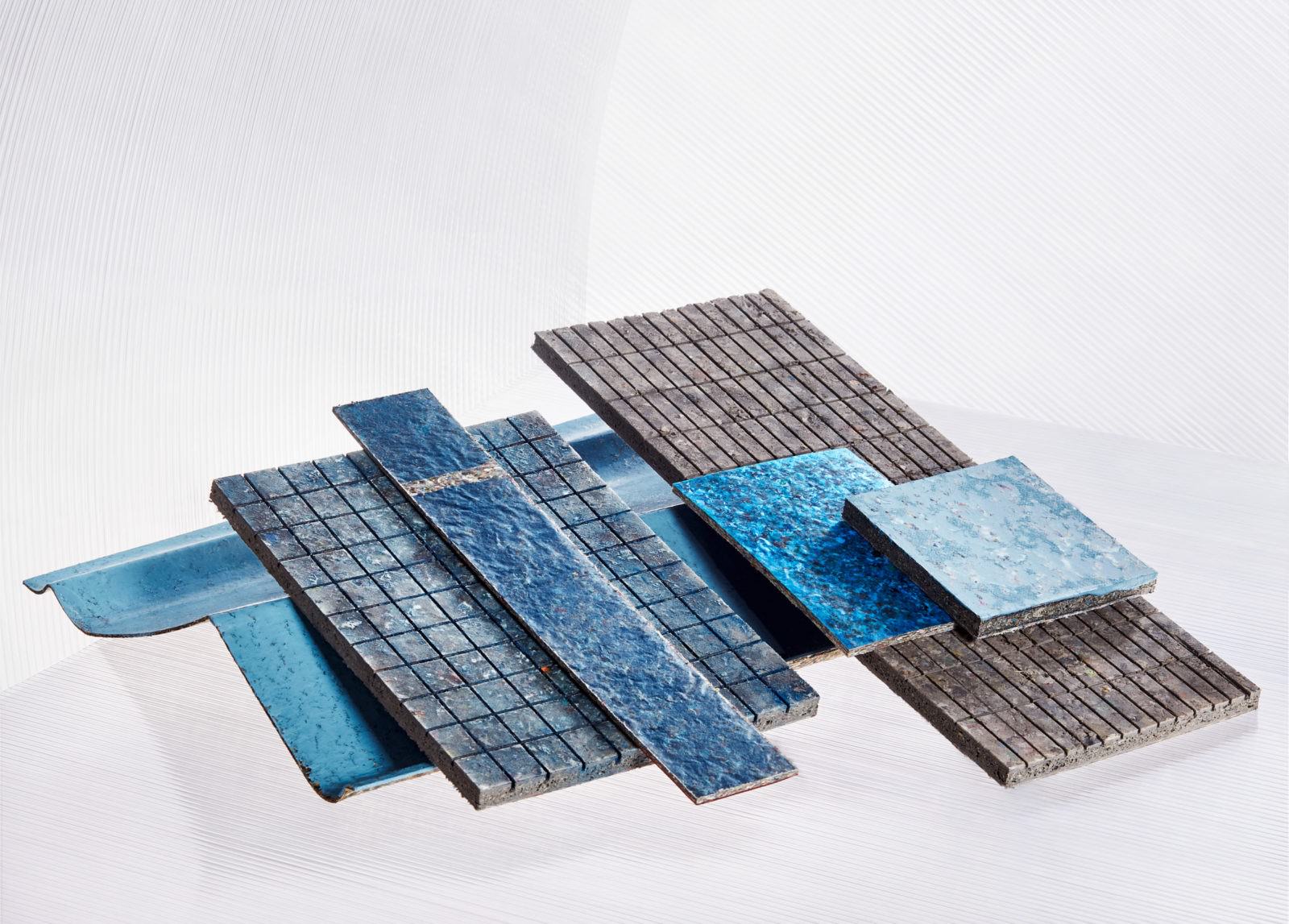

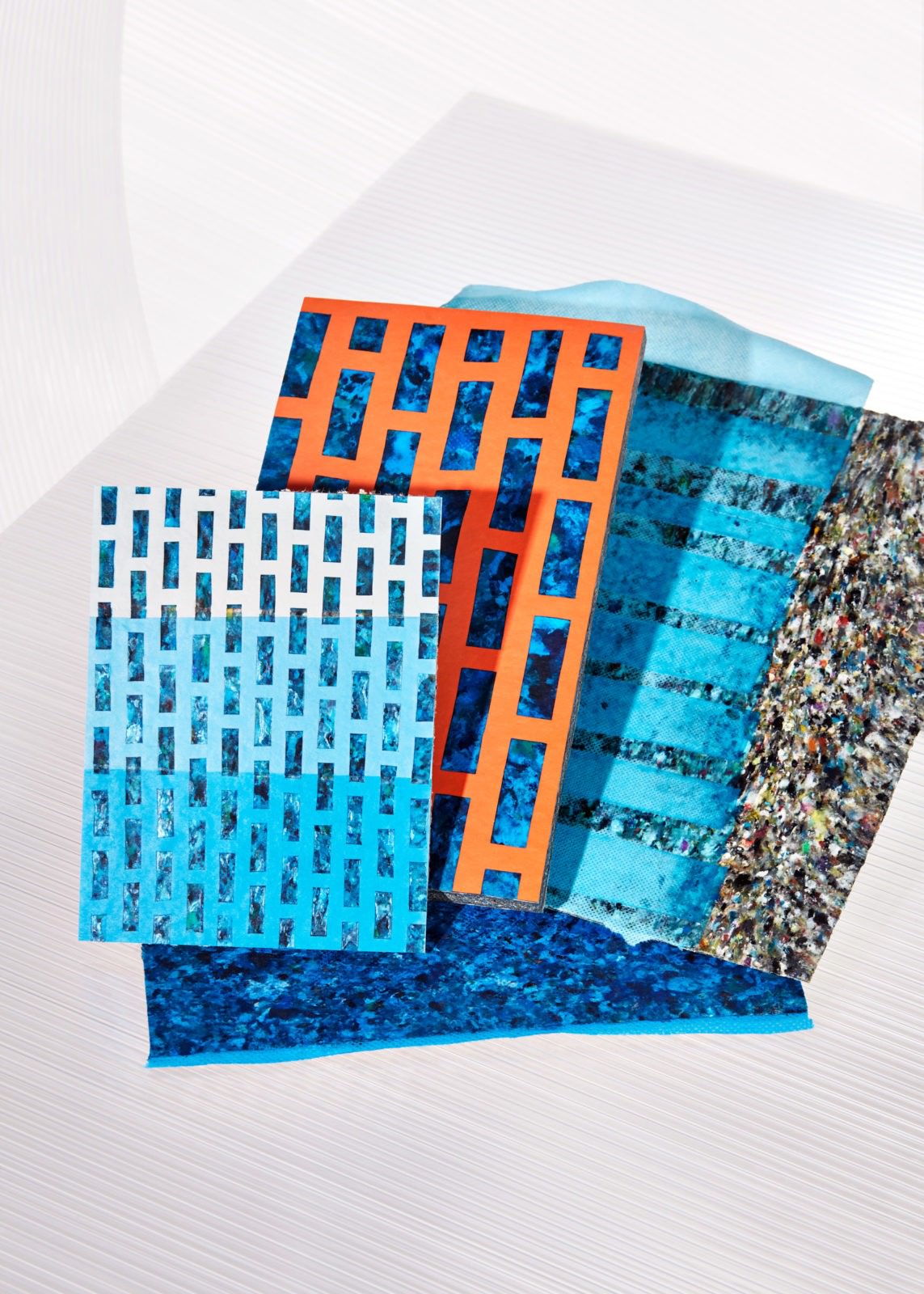

Recycled plastics in process

Design

Recognising the urgent need for a sustainable and recyclable board material in the market for construction and architecture, the design collective envisions and plastics recycling company ECO-Oh! have closely collaborated to develop an experimental demonstration for how recycled plastics can positively impact the future of materials. ECO-oh! distinguishes itself by not only recycling easily processable plastics—such as PET —but also finding ways to incorporate contaminated and complex plastics back into the cycle. By developing a composite board material – a flexible ‘mat’ consisting of washed plastic flakes and recycled PET fibres heated together – ECO-Oh! uncovered a technically inventive way to embed the complex plastics inbetween superposing consecutive layers, while giving rise to a high-performance material. Nine envisionaires were invited to analyze each component, gathering distinctive properties leading to new ideas for the development of this board material. Focusing on malleability, visual change or the minimal inclusion of material, they refined ways to make the mat suitable for interior and exterior context, while staying entirely recyclable. Adapting the malleability of the usually solid board by intervening with the heating process or manipulating shape provided grounds for varied constructive and spatial applications. Tijs Gilde adopted a vacuum membrane to transform the board into a modular building block using a mold. The added strength provided to the already durable and water resistant properties of the board gave use for modular facades or roof panel systems. Fred Erik developed a series of graphical recycled top layers for the composite board. In covering certain parts, he engaged in an aesthetic exploration of the tension between geometrically unfolded patterns and the boards prominent erratic flaky pattern. By adding a specific colour filter, different colour variations emerge from the flaky mixture. This created a wide variety of patterned boards with decorative potential for interiors. >recycled 3/5 plastics in process< marks the first step towards finding applications for complex plastics, that bear an aesthetic and intrinsic appeal while also being easily processed on an industrial scale.