FORBubblewraPACK

Packaging Solutions

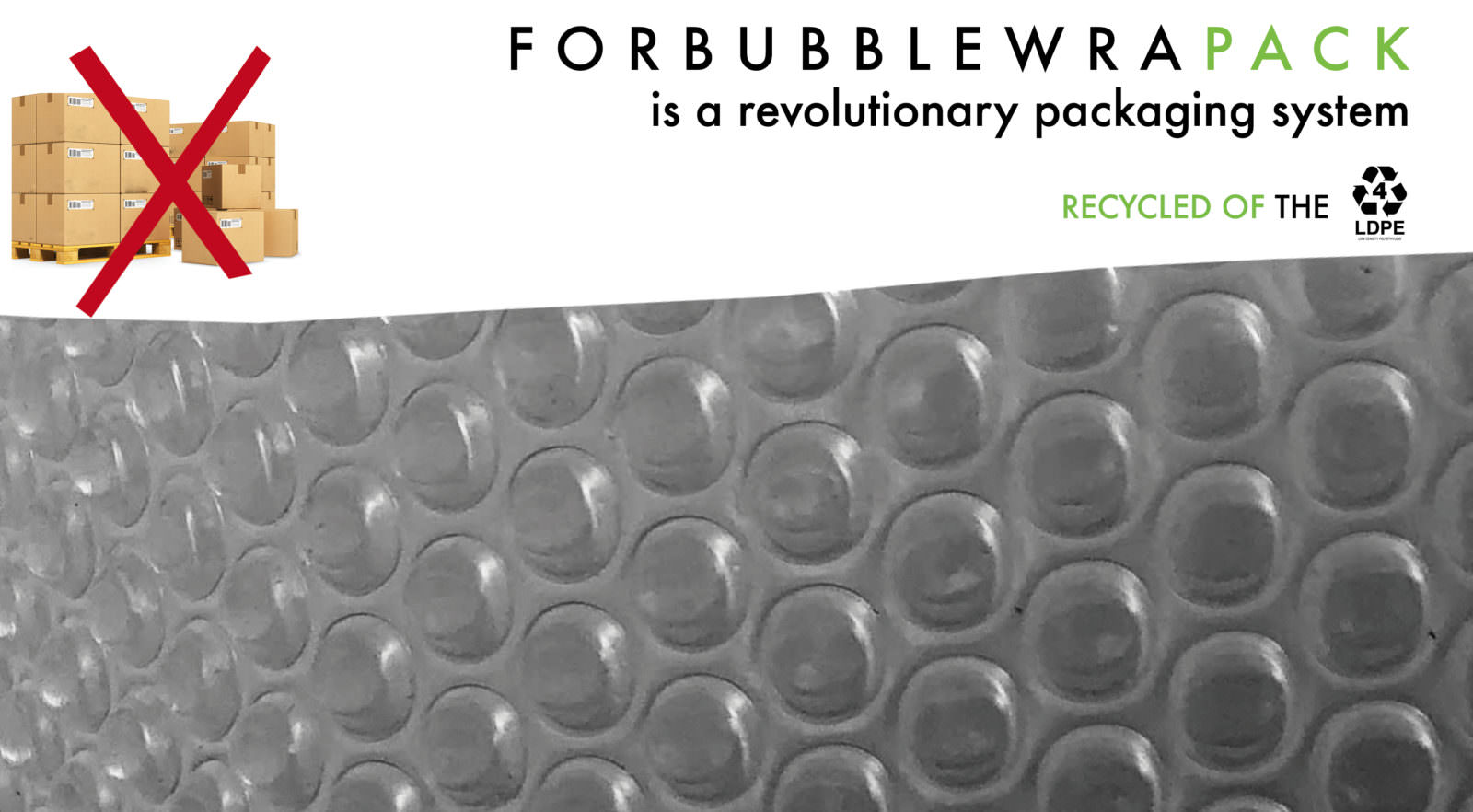

The title and a brief description of the project: FORBubblewraPACK An ambitious challenge in every respect, which pursues a twofold objective: on the one hand the recycling of plastic (low density polyethylene), on the other the elimination of all cardboard packaging. The result is a light, resistant, water-repellent, shockresistant, reusable and repairable packaging system that can be once again be recycled at the end of its working life. An explanation of the innovation and of what makes the project different from other products already on the market FORBubblewraPACK is a revolutionary packaging system, derived from recycling low-density polyethylene. This packaging combines the cushioning effect of a laminated wall of lightweight bubble wrap sheets with the protection of a harder outer shell, obtained from bubble sheet 12 times more dense, about 1500gr /m2, than the norm of 115 gr/m2. The system can be optimised and shaped according to the performance required. Thanks to a punching cutting system, packaging can be made to almost any shape and size. Recent estimates (Ellen MacArthur Foundation) show that today there are over 150 million tons of plastic in the world’s oceans. Without an effective turnaround by 2050, we will have more plastic than fish by weight. Not only that: plastic represents almost all (60-95%) of the waste found in the seas of the world and is the principle waste matter found on beaches and in marine sediments. On a planet that is increasingly polluted, plastic can be and must become a resource. The greatest use of plastics is made by the packaging industry (39.9% of the total). This is why I have focused on this aspect for the time being; the excellent performance possibilities of FORBubblewraPACK mean that it could be easily introduced into other product areas: from indoor and outdoor design to products for children. An explanation of how the project works FORBubblewraPACK is made from padded material obtained from a number of 3/5 overlapped, joined sheets: a hard bubble wrap welded to a variable number of standard bubble wrap sheets. The result is a very strong, flexible and shockproof exterior, and a soft, cushioning interior. The manufacturer will cut out the shape using a punch, in the same way as cardboard boxes are made. The cutting also welds all the layers of bubble pack and traps the air, which is a further guarantee of protection and lightness. For the first time, soft bubble wrap sheeting will be the entire packaging structure and not simply interior protection, rendering cardboard boxes, shipping bags and polystyrene etc. obsolete. One simple and practical piece to guarantee safety and protection from bumps, scratches and rain. Once a FORBubblewraPACK package has been opened, it becomes a sheet for reuse and re-labelling and, when necessary, is easily repaired. Once it becomes unusable it can be recycled again.